Design Review 1 + Feedback

- Team Blogger

- Mar 11, 2020

- 2 min read

After presenting our first design review (link here: https://docs.google.com/presentation/d/1rULD4nageM5t8KA6XSSOaYQsyBLwn7a8B6OC6F9iHdU/edit?usp=sharing), we got some really great feedback that we decided to incorporate (link here: https://drive.google.com/file/d/16H9Yd8j8j36xgzNlVFL9Oayz9qJZgU1l/view?usp=sharing). A 3D print of our design is below:

We all decided that, even though the design and implementation would be tricky, the worm was a key component of our design which we were willing to put the effort into making work. The main high level design question we then had was about thermoforming: thermoforming a basket, or thermoforming a bite mark? We decided to try and CAD, 3D Print, and Thermoform both for the next lab section, to get a better idea of the aesthetics of each. A thermoformed leaf, which was a previous consideration, was discarded because we all agreed that an injection molded leaf would likely look better, and be easier to manufacture.

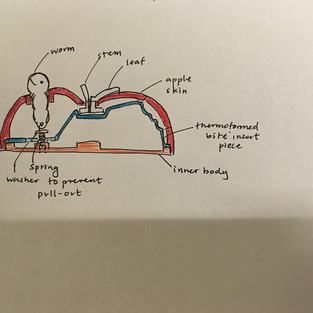

Another key point we discussed was the interactions between parts. At the design review, we presented a model that relied on multiple snap and press fits. We were told that the multiple tolerances on these would stack, and the parts would be very difficult to manufacture, in spec. Therefore, we came up with new interfacing between the different parts. The overall design of an apple top with a thermoformed bite on one side and a worm on the other is shown below:

The only closely toleranced connection is the snap between the inner body and the apple shell, which has a set interference amount. The thermoformed bite part fits in above the inner body. The worm is constrained by a collar in the shell of the apple, and attached to a spring. The head of the worm is larger than the hole, to prevent it from going inside the yoyo. The spring is attached to the inner body, through a hole in the thermoformed part. The stem and leaf are both T-slotted. The ledge rests on the thermoformed part. We plan to insert the leaf from the top of the shell, and then insert the stem from below. Although the production is still complex, it does not rely as much on tolerances, meaning that the parts are likely to fit together. The increased building time is something we agreed we were ok with!

In lab this week, we plan to show our new CAD models, our thermoformed bite and basket, and discuss the changes with the lab instructors. We are excited about the progress we’ve made :)

Comments